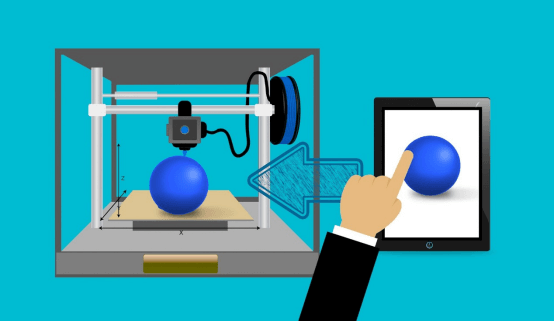

3D printing is gradually gaining traction for all the right reasons, and it is quite easy to see the reasons for its popularity. 3D printing is simply a process whereby solid objects are created via digital files.

Several decades ago, no one could have imagined the possibility of creating a solid object from a 2D design.

While many persons are getting to grasp the technology, a large percentage do not know how this technology works. If you’ve been looking to get yourself a DIY 3D printer kit for familiarizing yourself with 3D printers, this article could certainly prove helpful. Here are a few tips to help you through the process;

Conceptualize your design

An excellent way to start your 3D printing design journey is by first conceiving a clear idea of what you’re trying to create. This step makes the process of design more straightforward as you can readily preview the layout in your head. You could also picture the ideal size of the object you’re trying to create before setting out for the design phase.

CAD design

When you have a clear idea of what you’re trying to create, the next step is about designing a CAD file. CAD refers to computer-aided design, and these designs can be carried out using designated software. The CAD design process allows you to enter the required dimensions of the object; you can also create a virtual simulation environment to observe the behavior of the object in extreme conditions.

Format the CAD file

Once the CAD file design is done, the next thing step is to convert the file to a format the printer will accept. Usually, 3D printers have specific file formats; it’s essential to save the file to this format so that the printer can recognize and read the design. You could also set the size and orientation of the object to suit your needs.

Get the printer ready

To ensure that there aren’t hiccups while the printing starts proper, you must ensure that the 3D printer is in prime condition. Other things to check for include the positioning of the material.

Go ahead and print

The next thing to do after conducting all the necessary checks is to start the 3D printing properly. 3D printing works in such a way that layers of the material are added bits by bits until the required shape and dimension is reached; this is precisely why utmost patience is necessary as this might take a bit of time.

Retrieval and post-processing

Now that the printing is done, the 3D object can now be withdrawn from the printing machine. You must take necessary precautions when handling the object so as not to deform it in any way. The use of hand-gloves is also advised while retrieving the object as a form of safety.

Final thought

Creating 3D objects is not as daunting as it sounds and a little attention to detail is all that’s required. This article walks you through some of the steps involved in 3D printing.