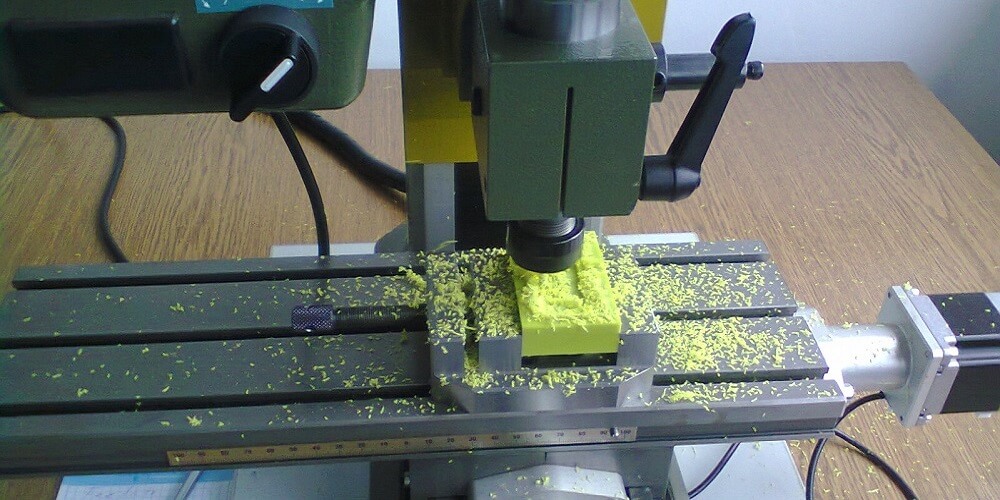

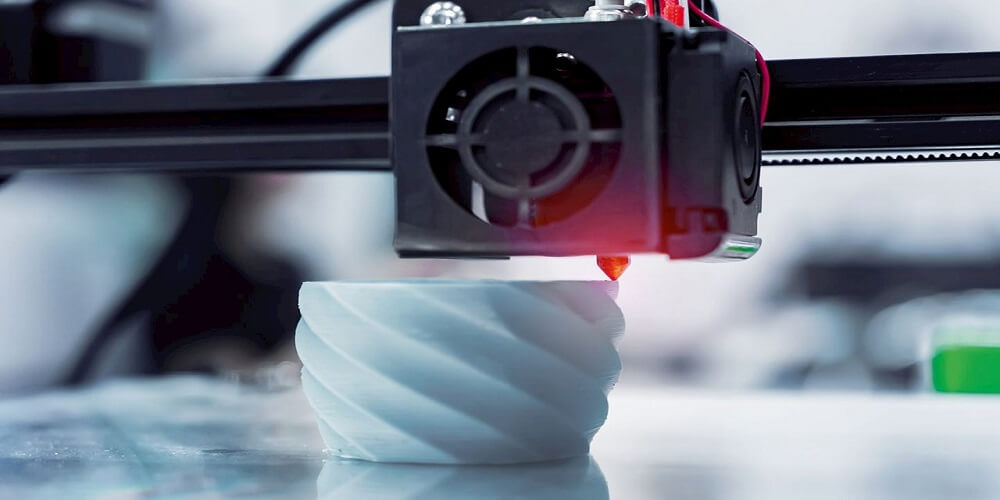

CNC machining is a fast and reliable method of machining parts. It uses machines with programmed software to control the manufacturing process. These machines are an essential part of most industries and have numerous advantages. Several well-established companies used them to offer various services to customers; however, they are costly to buy. Upcoming companies may find it difficult to buy brand new machines considering they require more than one piece. So, we look at the advantages of buying used CNC machines below.

Benefits of Buying Used CNC Machines

The high cost of these machines may be due to their high production rate and versatility, making them suitable for multiple applications. It’s arguably true that they are an investment but, the price may not fit the budget for some people.

1. Cost friendly

Used machines are pretty similar to new machines in terms of how they function. If the machine is well maintained and in good condition, the chances of producing parts with similar qualities as the new are high. You can buy these machines in auctions, second-hand shops, or from an owner wanting to dispose of his. No matter the price you purchase the device at, it’s still lower than the original price hence a great way to save your money. You can also get a well-known brand with good quality items at a low cost.

2. More flexibility

Since you can get the machine at a lower price, you can buy it for training purposes or a project in your company for a designated period then sell it off later to get back your investment. This works well for those who are aimed at gaining experience and not really owning the machine. In addition, using the machine for manufacturing parts in your shop is an added expense; however, it’s much better than new machines since the profits made can pay it off quicker since it’s cheaper.

3. Environmentally friendly

Buying used CNC machines is like reusing items that you would have discarded. Manufacturers are producing more and more machines to meet the demand. Also, some suppliers are replacing theirs with new ones; hence many are not in use. Getting pre-owned machines reduces their number and lowers the production of new ones. However, despite choosing to be economical and maintain the environment, ensure the machine function well and the controls work well with the modern software.

4. Avoid the initial depreciation

Like a car, the value of a CNC machine drops once it’s out of the dealership shop. Depreciation is estimated to be at its highest during the first year of purchase. It later reduces and drops at a much slower rate. Most of these machines are sold after a year of use, so you avoid the significant drop in value and still get a good machine for your work.

Conclusion

As seen above, used CNC machines are excellent and budget-friendly. Research on places to get these machines and take time to assess them before purchasing. Check the wiring, software, maintenance procedures, lubrication, and other elements. If everything is okay, the machine can serve you to produce the necessary parts for an extended period.