Prototyping is an inevitable technology in the world today. Very many engineering companies cannot avoid the use of prototyping services. Do you deal with the production of electronic, products, high-power machines among other electronic devices? You will need prototyping services and in this case rapid tooling services to manage your production services.

What is rapid tooling?

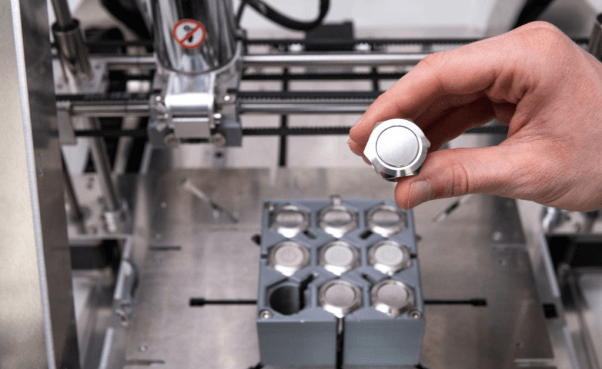

Maybe you have heard of this term in the industries and you have no idea what it means. Rapid tooling is the whole idea of carrying out Low volume injection moulding for plastic parts. This rapid tooling service can carry out moulding for a variety of products.

In order to achieve the best tooling services, you need to work with great tooling experts. This way you will be able to acquire services according to your needs and expectations. 3ERP are the best tooling service providers in the market today. They have been able to stand out in the market for a very long period due to their nature of service. Let us interrogate why they have remained the best tooling manufacturers in the market. It is best used for fulfilling small batch orders that can be used as marketing samples and process designs.

Quality Products

3ERP has never compromised their quality. Every time you want to purchase a product you will look at the quality the product will offer to you. You do not want to be in the market from time to time due to the failure of your products. 3ERP has the best quality tooling services you will always enjoy and recommend to your friends. They adhere to all the quality assurance protocols and thus have the certification to manufacture the tooling prototypes.

Professionalism

Whenever you want to buy a product you will likely try to look at the person offering to you the service in terms of the level of expertise in the field. You will have the satisfaction that you will receive the right service from the experienced one. In other words, you go to an expert to seek advice on what is best for your solution. In this case, it’s only an expert that will stand all these tests. 3ERP has the best-experienced personnel. They combine all their efforts and expertise to come up with the best product to solve your needs.

Economies of scale

A manufacturer using rapid tooling is likely to manage huge production at affordable service for an order. Therefore rapid tooling is very efficient for use when you need huge production.

Diverse materials

Rapid tooling allows for a variety of materials in use. There are not many limitations for the injection moulding hence very recommendable by everyone for use. At 3ERP you will receive rapid tooling for the materials you will need moulding injection on.

Customizable finishing

You need that manufacturer who will be able to do rapid tooling services at your preference. Do you need a smooth texture, glossy or textured finishing? 3ERP will provide you with the right customizable services. Chroming, painting and silk screening can be applied to the mould.