In the realm of production and engineering, the demand for precision and tailor-made answers has brought about the upward thrust of custom aluminum parts. From electronic goods to the military, these accurately crafted, specially designed parts have revolutionized a number of areas.

However, when it comes to difficult technical problems, the sole length that works for all approaches frequently fails. That’s what unique parts made of aluminum come in, providing tailored solutions that exactly match specific needs.

Crafting custom aluminum elements includes an aggregate of advanced technology and professional craftsmanship. The system usually includes the following steps:

Layout and Prototyping

The journey starts with designing the component based on the customer’s necessities. Computer-aided design (CAD) software is used to create unique three-D fashions. Prototyping follows, taking into account trying out and refinement before full-scale production.

Cloth Selection

Aluminum alloys are chosen based totally on factors such as electricity, corrosion resistance, and thermal conductivity.

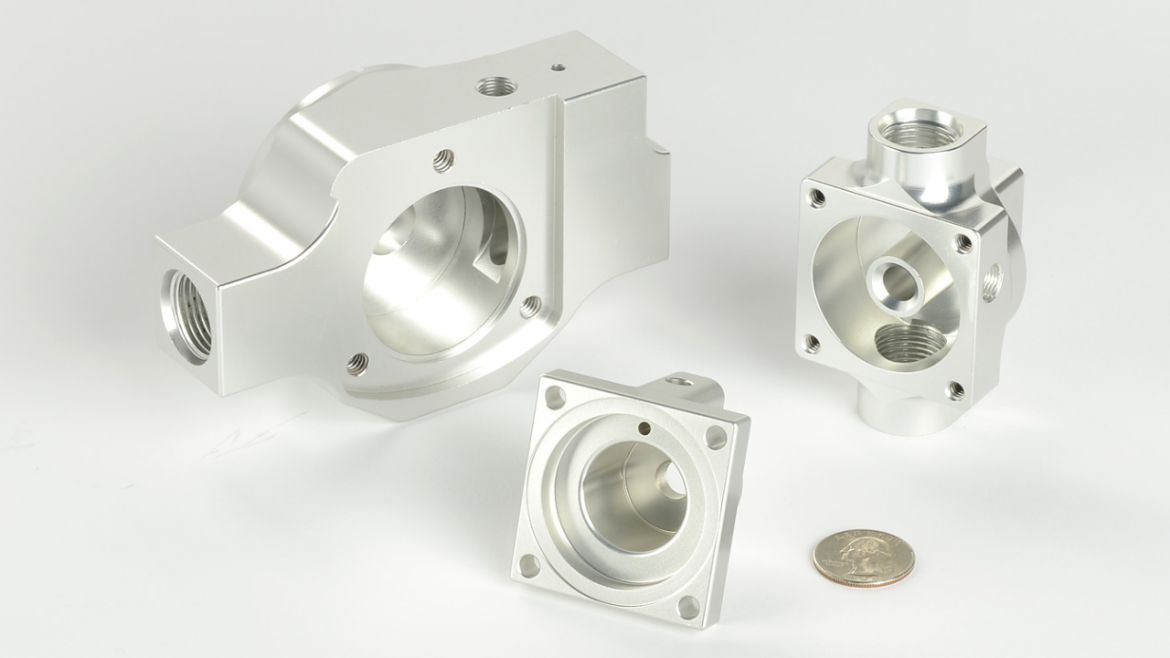

CNC Machining

Computer Numerical manipulation (CNC) machining takes center degree within the production technique. CNC machines comply with unique instructions to form the aluminum block into the preferred component. Accuracy, reproducibility, and the ability to produce complex geometries are all guaranteed in this way.

Completing Floor Treatments

Completing steps, including polishing, anodizing, and powder coating, decorate the component’s aesthetics and capability. Anodizing, in particular, provides a protective layer to the aluminum, growing its resistance to put on, corrosion, and environmental elements.

Custom aluminum parts discover software in a numerous range of industries, each taking advantage of the precision and adaptableness these additives offer.

Aerospace and Aviation

Inside the aerospace sector, in which weight reduction and excessive performance are paramount, custom aluminum parts play a critical role. From difficult brackets to structural additives, those components are designed to withstand the stressful conditions of flight while optimizing gas performance.

Automotive Engineering

Automotive producers use customized metal parts to make small yet durable pieces that increase vehicle performance and fuel efficiency. Engine elements, suspension components, and body panels are examples of regions in which custom aluminum solutions are hired.

Innovation and electronics

Precision parts that can be molded into small devices without sacrificing functionality are required by the rapidly changing electronics industry. Engineered aluminum components offer the required complexity, enabling the creation of heat sinks, structures, and connectors that especially meet the needs of cutting-edge current designs.

Commercial and Manufacturing Equipment

Bespoke metal parts are used in corporate settings to design machines and systems that are suited to particular production methods. Conveyor infrastructure, unique instruments, and other operations are all made faster and more efficient by these upgrades.

Favorable Features of Custom Aluminum Part

Custom aluminum parts offer a plethora of benefits that extend beyond widespread components:

- Tailoring elements to precise necessities ensures a particular fit, decreasing the need for adjustments and changes in the course of assembly.

- Through adjustment, extra fabric can be cut out to provide fewer components that enhance the functionality of the overall machine.

- Via optimizing design and fabric choice, custom aluminum elements can decorate overall performance characteristics together with energy, thermal conductivity, and corrosion resistance.

- Custom components can be made to integrate easily with existing systems and assemblies, lowering the difficulty and length of lead times in production.

Finally

The highest point of precision engineering is custom aluminum engineering, providing industries with outstanding efficiency, weight reduction, and capability with solutions that have been developed specifically for them. These parts evolved how things are designed and made, from electronics to aerospace.