A CNC machine is also fondly known as a Computer Numerical Control machine. It basically runs on a computer program-meaning; it can be used in prototyping or better yet full item production. Too often, aluminum is the commonly applied material since it exhibits exceptional machinability, thus making it the preferred material in manufacturing sectors. As the primary material, aluminum provides impressive thermal as well as mechanical properties.

Other than that, the metal is pretty much easy to shape, particularly when it comes to drilling processes, such as in aluminum CNC machining. As experts, we highly regard aluminum alloy more than lightweight materials like titanium alloys.

The applications of CNC aluminum have grown tremendously in the production of automotive parts coupled with crucial CNC parts. Below are a few basics of everything you need to know about aluminum CNC machining.

Background Check On The Material

Aluminum is a naturally soft, tractable, and durable element. It has a silver appearance that comes with a dull grey look depending on the robust nature of the surface. Usually, it lacks specific magnetic properties. It is also highly non-flammable.

Towards that end, it is essential to note that it melts at about 620 degrees Celsius and has a density of 2.60. The material is also an excellent conductor of heat and electricity. For that reason, it is often used in the industry of CNC automotive machinings such as medical sectors and aerospace.

Aluminum Grade

This is the ultimate selection of the aluminum grade most professionals intend to use. Your choice depends on the machining projects that you have since they should allow you to rank every grade according to the characteristics, mostly from the most crucial one to the least. When that is achieved, you will be in a position to select a specified aluminum for CNC machining projects.

The following are just a few types of essentials facts regarding aluminum grade:

Aluminum 6061– this is one of the superb grades on the market. It has excellent mechanical properties, including weldability. The topical properties it comes with make it an extruded grade since it comes with a tough nature and medium strength.

The material is often used for the famous five-axis machining. But it is not suitable for welding since it is pricey. And hence, it is perfectly fine for tough parts, including fuselages and bicycle parts, as the alloy is corrosion resistant.

Aluminum 2024 – in this type of material, the alloy is used in the military as well as the aerospace sectors. This is appended to the fact that it has excellent chemical properties such as perfect weariness resistance as well as high strength.

Final Thoughts

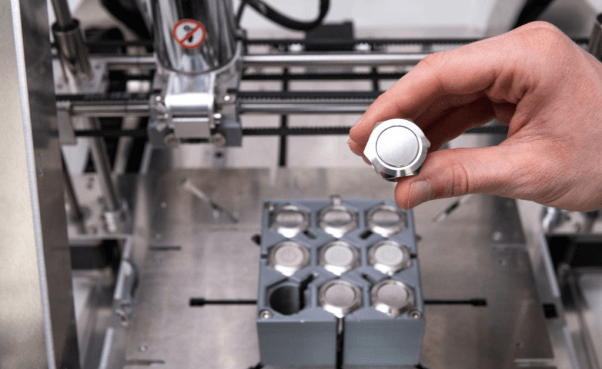

Typically, the CNC machined aluminum technology has significantly produced different CNC parts, which aid in multiple services such as turning, grinding, as well as milling. In the current world, accurately machined CNC aluminum parts have been growing in popularity in the sector of engineering.

Some of the parts are such as:

- Dowels pins

- Spline shafts

- Front panels

- Lighting fixtures