When deliberating in between product options and general industrial piping system design, the main considerations revolve around pipes and fittings. Particularly, the focus is typically on the pipeline and fitting products’ temperature level, compatibility and pressure attributes.

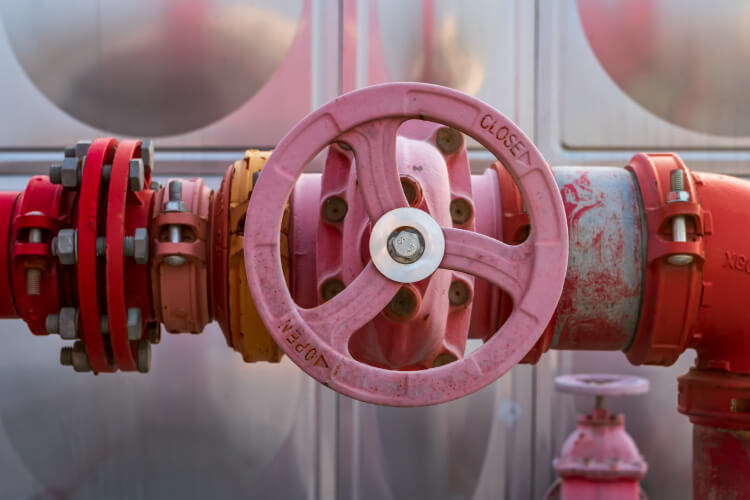

As soon as those main decisions are settled, valve choice is frequently an afterthought finally thought about. However valve decisions are huge: types consist of ball valves, gate valves, world valves, butterfly or wafer valves, inspect valves, diaphragm valves and more. The number of valves can differ greatly in a system depending on the function of the piping system.

Valves are vital to any successful system due to their significance in controlling the circulation. Due to the fact that a system is only as strong as its weakest component or joint, valves are worthy of much higher attention when considering material alternatives.

The Purpose of Valves

In a general sense, valves restrict, stop, or control the circulation of fluid through a piping system. More particularly, a system of valves might remain in location to:

Control the cooling rates of water through cooling lines to manage the temperature.

Handle the flow of concentrated acids or bases streaming through a line.

Redirect circulation from one line to another at a three-way valve.

Limit flow for system balancing.

Prevent reverse flow through check valves.

Automatically stop the circulation in the event of a system failure.

Why Valves Matter

With such a substantial function in increasing efficiency, improving safety and keeping systems up and running, why are valves seldom gone over at the outset of planning a piping system?

One explanation might be the minimal cost connected with valves, especially when compared to the total cost of a system of large, Schedule 80 fittings and pipes. By examining valve choices of different materials earlier in the product choice and style process, systems can end up being more efficient, reputable and cost-effective.

How Valves Impact System Efficiency, Cost and Reliability

A common assumption is that the weakest point in any commercial system exists at the valves. This is not always the case. Depending on the chosen pipe and fitting product, valve product and joining approach, numerous valves can promote the very same performance standards as the remainder of the piping system.

When identifying the total system pressure score, it is an excellent engineering practice to identify the weakest part in any system. Valves utilized in non-metallic systems should always be thought about for pressure abilities in particular, as they can differ by manufacturer.

In what ways do valves impact an industrial piping system?

Deterioration Susceptibility

When working with acidic and/or caustic services, increasing the life of a system is vital. Deterioration is the offender of numerous system problems, triggering early repairs, pricey downtime and even total replacement. Each of these setbacks results in substantial costs and is reason enough for engineers to pursue chances to increase system life.

Products that are prone to rust frequently experience it at joints. The more system components included, including fittings and valves, the higher the chance of corrosion afflicting the system.

Even if rust does not harm a system to the point of needing immediate repairs, it can damage the valves. Valves are especially susceptible to both corrosion and degradation of the valve seats. Corrosion produces particles and scale that can make valves harder to move, making systems less efficient, or cause considerable security issues in case of a failure.

When the line is heat traced and the product is not corrosion-resistant, Electrochemical rust is a specific type of corrosion more typically experienced at valves.

In each case, CPVC is more rust resistant than metals against most salts, bases and acids utilized in industrial processing. To enhance the system’s life, consider the increased danger of rust at valves.

Pressure Loss

To avoid unneeded energy intake expenses, industrial systems must optimize fluid characteristics. One way to do this is to reduce pressure drop or head loss.

One cause of pressure drop in piping systems is valves. Each valve has a recognized circulation coefficient, which is used to compute the pressure drop (P) it triggers when in the completely open position. This circulation coefficient is the volume that will flow through the valve with a pressure drop of 1 psi throughout the valve. The larger the valve flow coefficient, the less pressure drop it will trigger.

flow rate pressure drop valve formula in piping

To enhance effectiveness and limit energy intake, plants choose a valve with a greater circulation coefficient. Valve makers supply valve flow coefficients for each product.

On a macro level, the pressure loss in valves is lower for a lot of thermoplastics than metals. CPVC valves, specifically, interfere with the circulation in commercial piping systems less than the valves used for metal systems, much better preserving circulation rates, and effectiveness.

A couple of factors for this consist of metal’s vulnerability to corrosion, scaling, rust and other mechanisms that minimize pipe, fitting and valve interior smoothness.

System Weight and Stress

Each part connected to or integrated in a system, consisting of valves, increases stress on the pipeline. More system stress increases the possibility of breaks, leaks, misalignment and joint failure.

A couple of considerations when utilizing valves:

Each valve increases the total stress placed on the piping system.

Valves might need assistance, specifically if the valve is heavy.

Metal valves are heavier than a lot of thermoplastic valves.

CPVC is 1/6th the weight of comparably sized steel, which is intensified for strong valve elements installed throughout the line.

Pressure Rating

The portion with the most affordable pressure rating ends up being the system’s restricting factor when it comes to push ranking a system. Usually a valve placed into the line has the lowest pressure rating, making it the limiting factor to the general pressure score of the system.

Comprehending valve pressure ratings is crucial due to the fact that a system is only as strong as its weakest link.

And despite what numerous assume, the valve does not have to be the system’s pressure restraint. The elements for valve pressure rankings are:

Product type. In plastic systems, the valves or flanges usually end up being the limiting element if plastic valves are set up.

Connection type or joining technique. When metal valves are set up in plastic systems, the connection type usually dictates the pressure rating of the system. Plastic flanges not strengthened with suitable flange kits will just have a pressure rating of at 150 PSIG at space temperature and derate as temperature increases. Typically, industrial CPVC valves have an option to make use of socket joints, which permit the system to have a much higher rating at space temperature. In addition, the utilization of CPVC valves alleviates the corrosion issues of metal valves.

Numerous CPVC valves hold true union valves and are rated at 250 psi at 73 ° F (23 ° C), making the pressure rating of a CPVC system appropriate to manage the extreme conditions of the majority of chemical systems.

Follow maker suggestions for pressure ratings and temperature level derating aspects above space temperature level.

Further Compare Metal and CPVC Piping Materials

CPVC piping is not new to the market, and it is ending up being the product of choice for numerous engineers and plant supervisors in the industrial space. Discover how CPVC compares to the conventional option, metal, in a variety of classifications, consisting of:

Pressure resistance

Rust resistance

Set up cost

Safety

Valve decisions are huge: types include ball valves, gate valves, world valves, butterfly or wafer valves, inspect valves, diaphragm valves and more. Depending on the picked pipeline and fitting product, valve material and joining method, lots of valves can uphold the same performance requirements as the rest of the piping system.

CPVC valves, specifically, interfere with the circulation in commercial piping systems less than the valves used for metal systems, better maintaining circulation rates, and effectiveness. In plastic systems, the valves or flanges usually end up being the limiting factor if plastic valves are set up. In addition, the usage of CPVC valves alleviates the deterioration concerns of metallic valves.