Traditionally, if companies wanted to introduce a new product to the market, they had to develop a design then manufacture it. Most companies would depend on their clients to point out defects in their products to make alterations. However, this is currently not the case. Due to the increasing demands in the market, companies have to create prototypes as part of the product development stage. Creating prototypes helps manufacturers meet the market demands, save on cost, and reduce the timeline of their projects. There are various types of prototyping services. Companies often have to choose the best prototyping technique.

Prototyping techniques

There are two primary prototyping techniques that companies use. They are:

1. Prototype machining

Prototype machining, also known as CNC machining, is the newest and the most popular technique. This technique is CNC (Computer Numerical Control) based. The prototyping machine tools get their design instructions from a G-code created in computer software known as the CAD software. The instructions are then fed into a computer which translates it into a series of instructions that the tool can understand.

Once this is done, the machine does not require a lot of manual supervision since it already knows the exact dimensions and design instructions that it has to follow. In simpler terms, the machines operate autonomously. All these elements result in the fast and efficient creation of the prototypes. It is worth noting that CNC machining is a subtractive method of manufacturing.

2. 3D printing

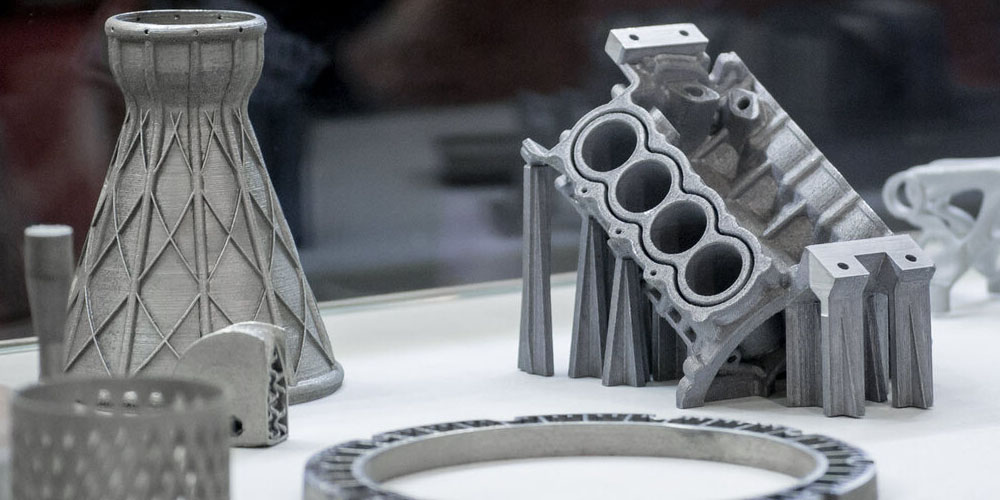

The second technique, which most companies have preferred for a long time, is 3D printing. 3D printing is also an efficient method of creating prototypes. It starts by designing the part in a computer. The design elements and instructions are then sent to the 3D machine via the computer. The 3D machine uses additive manufacturing to create the part using a 3D printer. In this technique, there are tool paths used to dictate instructions to the machine.

Which of the two techniques is better?

For a long time, companies preferred 3D printing. This is mainly because 3D printing is less complicated and requires less setup. However, recently, CNC machining has become the most popular technique for prototype machining. Below are some reasons why CNC machining is a superior option;

- The process is faster

- It produces quality parts

- It allows you to use robust and durable materials like a wide range of metals

- It offers a high level of repeatability and consistency

- It creates prototypes that are very similar to the final product

- Companies also love the fact that the technique can also be used to create the final part

While CNC machining is an ideal technique, it does not mean that 3D printing has completely been done away with.

Conclusion

Note that most of the benefits mentioned above cannot be achieved through 3D printing. Regardless, when choosing the best option between the two techniques, most manufacturers consider the type of product they want to create and the materials required. This is vital because both of the techniques offer significant benefits. It would be easier to make an informed decision if you compared the two techniques carefully.